The Facts About Dust Extractor Vs Shop Vac Uncovered

Wiki Article

The Basic Principles Of Dust Extractor Vs Shop Vac

Table of ContentsThe Only Guide to Dust Extractor Vs Shop VacGet This Report on Dust Extractor Vs Shop VacGetting My Dust Extractor Vs Shop Vac To WorkAn Unbiased View of Dust Extractor Vs Shop VacThe smart Trick of Dust Extractor Vs Shop Vac That Nobody is Discussing

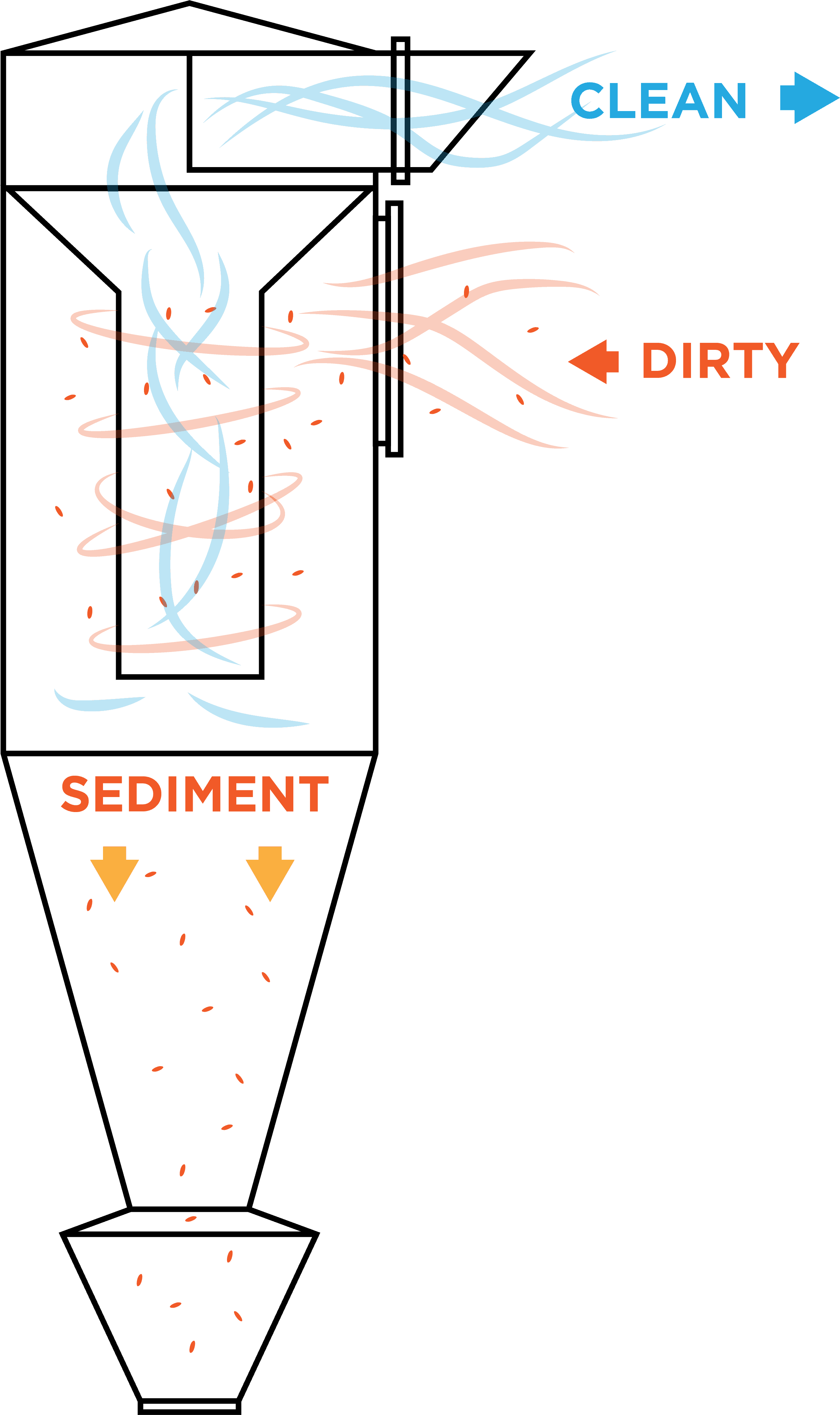

Before the advancement of dirt collection systems, dust surges, particularly in woodworking shops, were extremely usual. The problem was so widespread that lots of shops had a wall available to the exterior. Similar to fire avoidance, dust collection systems maintain air moving as well as distributing to avoid the possibility of dirt collecting adequately to create an explosion bubble.

Though dirt collection systems may obtain puzzled with a/c, they have much more benefits. When contaminated air is sent out with filtering, it eliminates the contaminants and odors they create. Smell reduction is not common in all dust collection systems. Where odor is a problem, carbon-impregnated filters are utilized. One of the major areas of worry for the Occupational Safety and also Health And Wellness Administration (OSHA), the National Institute for Occupational Health And Wellness as well as Safety And Security (NIOSH), and also the Center for Disease Control (CDC) is the safety of the workspace for employees.

The Only Guide for Dust Extractor Vs Shop Vac

Violation of these requirements can bring about an organization being closed, which makes it important to install an acceptable dirt collection system. Something that is seldom thought about in an industrial environment is the sanitation and also top quality of the flooring. One of the benefits of a dirt collection system is the removal of the requirement to frequently clean the floor.

Compliance with government policies is the most important of all the motivating variables for installing a dirt collection system. Firms that do not have the correct particle percent can be fined or required to cease procedures. OSHA and also NIOSH very closely keep an eye on potentially dangerous working conditions and do random inspections. A dirt collection system is necessary for any kind of market that produces gasses, dust, overspray, or various other types of particulate issue.

The Best Guide To Dust Extractor Vs Shop Vac

A number of the procedures that make use of dust collection systems are mainly concerned concerning safety and security given that several procedures involve the use of gasses. Plasma cutters generate fine smoke and also fumes, which need to be eliminated to shield the operator. Dust collection systems for plasma cutters use see post specifically made downdraft tables to draw the fumes away from the work space and workers.Various sorts of dirt collection systems are made use of to capture and gather the hazardous matter created by welding. Given that welding fumes and dust can be eruptive, the product produced should be checked for its fire and also eruptive qualities according to the standards of OSHA and the National Fire Security Association's, Organization (NFPA).

The volatility of the dust from seed and also grain operations is so high that OSHA has a collection of standards specifically developed for these operations. Dust from seed and also grain procedures differs according to the kinds of products being moved. It can be rough, sticky, or extremely fine. This is further complicated by the wide array of equipment used in seed and grain operations, which include conveyors, elevators, containers, various forms of vents, silos, and mixers.

Getting The Dust Extractor Vs Shop Vac To Work

Baghouse collection agencies are made use of for their high effectiveness of 99% and integrity. The preliminary issue for air quality in the office started with woodworking considering that it produces big volumes of sawdust and also fumes. As producers have explored the different woodworking procedures, they have located that a wide range of particulate issue is produced.Lumber mills and sawmills need various dirt collection systems Homepage than timber pellet makers. Each kind of operation needs a various type of collection system. No matter the kind of woodworking operation, timber dirt has been located to be the major reason for dirt mishaps. The threats of dust from woodworking procedures are very undervalued.

Both sorts of dirt collection systems for woodworking operations are cartridge and baghouse, with baghouse being one of the most reliable. Regardless of the type of system selected, it needs to be designed and also engineered to particularly fit the procedure and also manufacturing procedure of the consumer. The central worry for dirt collection systems in the food handling industry is transport, storage space, and mixing, which are the areas that collect one of the most dirt.

What Does Dust Extractor Vs Shop Vac Mean?

Food processing includes conveyors, packing equipment, mixers, shelling machines, and concentrated storage areas. Filtration systems can be connected to all tools and also places. The unique requirements of food handling need stainless steel because it is approved for procedures associated with food manufacturing. The two agencies that manage air high quality for mining why not check here operations are the Epa (EPA) and also the Mine Security and Health Management (MSHA), a branch of the Department of Labor.Dirt control systems for mining operations should withstand hefty usage yet be adaptable adequate to adapt to a wide array of conditions. The nature of mining dirt requires very tough and trusted devices since mining dust can be rough and also abrasive in addition to extremely fine. The different sorts of mining determine the kind of dirt collection system (dust extractor vs shop vac).

No matter the operation, mining dust control systems are created to suppress explosions, isolate fumes, as well as control smells from gasses. The usual types of dust collection systems for mines are baghouse and also cartridge. Fiberglass dirt is a serious health and wellness threat that can create eye, skin, and lung inflammation. The dimension of the dirt fragments varies depending on the kind of operation, with specific resins having the prospective to combust.

Report this wiki page